Waste tire disposal has become a huge problem today. Disposing of waste tires affects the environment and local landfill capacity. Recycling waste tires is quite a profitable business, and it also helps save the environment. Investing in a tire pyrolysis plant is the best way to recycle waste tires and sell the end products at a good price. The end products of waste tire pyrolysis are carbon black, steel wire, and fuel oil. All these products have high demand in the market and could make you a handsome profit in the process. Here are some of the most important factors to consider when investing in a tyres pyrolysis plant.

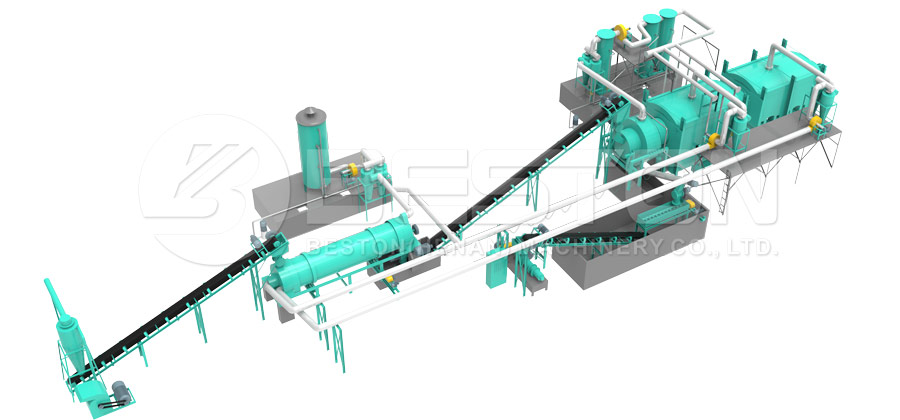

Waste Tyre Pyrolysis Plant Installed in China

Pyrolysis machines come in different sizes, shapes, and capacities. You need to invest in the right capacity depending on the volume of tires you recycle at a given time. Many people make the mistake of buying as much capacity as they could afford. If you invest in a 100-ton machine and use only 70% of its capacity, it increases the cost of production, and you may not be able to match the prices of your competition. Make sure you consider the demand for the end products and the availability of raw materials when investing in a quality tire pyrolysis machine on the market. Get the tyre pyrolysis plant cost.

Never underestimate the importance of after-sales service when buying a pyrolysis machine. The latest machines use hundreds of advanced components and require periodical servicing to operate optimally. Each part will play a crucial part in the production process. You should have quick access to replacement parts in case the unit breaks down due to whatever reason. If not, you might be forced to shut down production and lose money in the process. That is where after-sales service comes in handy. With excellent after-sales service, there will be fewer problems to deal with in your pyrolysis unit.

Waste Tyre Pyrolysis Machine Shipped to Ukraine

The waste tire recycling business is a profitable and eco-friendly venture. You need to invest in the best pyrolysis unit to operate a profitable tire recycling business. Take this pyrolysis oil plant project report. There are many factors to consider when investing in the best tire pyrolysis machine in the market. The aforementioned article offers information on what you need to consider when buying a quality tire pyrolysis plant.