In the world of egg production and packaging, the reliability and quality of egg tray machines play a crucial role in ensuring efficient and cost-effective operations. However, with a multitude of manufacturers vying for attention in the market, selecting a trustworthy supplier can be a daunting task. Fear not! This comprehensive guide is your roadmap to navigating the labyrinth of options and identifying the perfect egg tray machine manufacturer for your needs.

Understanding the Importance of Choosing the Right Manufacturer

Before delving into the intricacies of finding a trustworthy egg tray machine manufacturer, it’s essential to grasp why this decision holds such significance. The egg tray machine serves as the linchpin of egg packaging operations, responsible for molding pulp into sturdy trays that cradle delicate eggs during transport and storage. Opting for a subpar manufacturer can result in production delays, inferior product quality, and increased maintenance costs, ultimately undermining the efficiency and profitability of your business.

Key Criteria for Evaluating Egg Tray Machine Manufacturers

Technical Expertise and Experience

When assessing potential manufacturers, prioritize those with a proven track record of technical expertise and industry experience. Look for companies that have been in the business for an extended period, boasting a portfolio of successful installations and satisfied clients. Seasoned manufacturers are more likely to possess in-depth knowledge of egg tray machine design, engineering principles, and production processes, ensuring superior performance and reliability.

Product Quality and Innovation

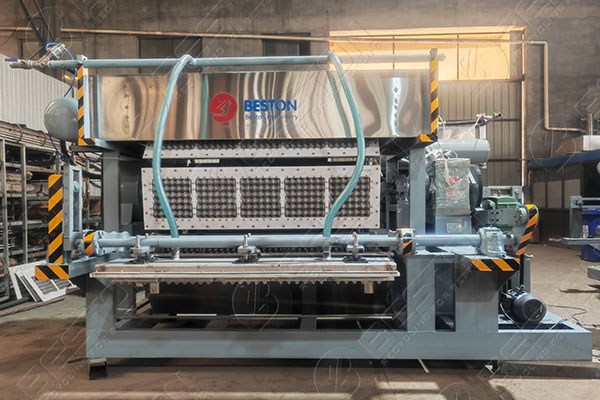

Scrutinize the quality and features of the egg tray pulp molding machine offered by each manufacturer. Seek out suppliers that prioritize innovation and continuous improvement, evidenced by the incorporation of advanced technologies, ergonomic design elements, and durable construction materials. Pay close attention to details such as mold precision, control system capabilities, and energy efficiency, as these factors directly impact machine performance and product consistency.

Customization Options and Flexibility

Every egg production facility has unique requirements and operational constraints that necessitate tailored solutions. Choose a manufacturer that offers customization options and flexibility in machine design, allowing you to adapt the equipment to your specific needs. Whether it’s adjusting production capacity, mold configurations, or automation levels, the ability to customize ensures optimal efficiency and compatibility with existing workflows.

After-Sales Support and Service

The relationship with a manufacturer doesn’t end after the purchase of an egg tray machine—it’s just the beginning. Prioritize suppliers that provide comprehensive after-sales support and service, including installation assistance, operator training, maintenance programs, and spare parts availability. Prompt and responsive customer support is essential for troubleshooting issues, optimizing machine performance, and minimizing downtime, ultimately maximizing the return on investment (ROI) of your equipment.

Reputation and References

A manufacturer’s reputation within the industry and feedback from previous clients serve as invaluable indicators of reliability and trustworthiness. Conduct thorough research by reading customer testimonials, case studies, and online reviews to gauge the experiences of other egg producers with the manufacturer in question. Additionally, don’t hesitate to request references or contact existing clients directly to inquire about their satisfaction with the equipment and service provided.

Steps to Finding a Trustworthy Egg Tray Machine Manufacturer

Conduct Extensive Research

Start your search by compiling a list of potential egg tray machine manufacturers through online searches, industry directories, trade publications, and referrals from colleagues or industry associations. Evaluate each manufacturer’s website, product literature, and online presence to gain insights into their capabilities, product offerings, and company values.

Request Information and Quotations

Reach out to the shortlisted manufacturers to request additional information, product specifications, and quotations for their egg tray machines. Be clear and specific about your requirements, production volume, budget constraints, and any customization needs to ensure accurate proposals. Take note of response times, communication clarity, and willingness to accommodate your requests as indicators of the manufacturer’s commitment to customer satisfaction.

Schedule Site Visits and Demonstrations

If feasible, arrange site visits to the facilities of top-tier manufacturers to observe their production processes, quality control measures, and manufacturing capabilities firsthand. Request live demonstrations of their egg tray machines in operation to assess performance, efficiency, and ease of use. Pay attention to details such as build quality, machine ergonomics, noise levels, and operator interface to form a comprehensive evaluation.

Evaluate Proposals and Compare Options

Carefully review and compare the proposals and quotations received from each manufacturer, taking into account factors such as equipment specifications, pricing, warranty terms, delivery timelines, and after-sales support offerings. Consider the overall value proposition and long-term benefits rather than solely focusing on upfront costs. Engage in negotiations to address any concerns or clarify terms before making a final decision.

Seek Recommendations and Validation

Seek input from industry experts, consultants, and trusted colleagues who have experience with egg tray machines and manufacturers. Their insights and recommendations can provide valuable perspective and help validate your choices. Additionally, consider attending industry conferences, trade shows, and networking events to connect with peers and gather firsthand experiences and recommendations. Welcome to contact Beston China to obtain the egg tray production plan.

Conclusion

Selecting a trustworthy egg tray machine manufacturer is a critical decision that can significantly impact the success and efficiency of your egg production operations. By adhering to the key criteria outlined in this guide and following a systematic approach to research and evaluation, you can confidently navigate the selection process and identify the perfect partner for your egg tray machine needs. Remember, investing time and effort upfront to find the right manufacturer will pay dividends in the form of reliable equipment, enhanced productivity, and long-term business success.