The harvesting of rice is a very profitable business. This is a type of food that is used by nearly every country. When the harvesting is done, the residue from the harvest is often used for fertilizer. If not, it can be sent to other locations for processing. This can be a costly endeavor that may cut into the profits of any business that is harvesting rice. However, if you could convert this material into something different, you might be able to save money. It is for this reason that many companies are investing in a charcoal manufacturing plant for this exact purpose. These machines are very easy to use and are designed for both larger and smaller businesses.

Rice Husk Charcoal Making Machine

Rice Husks And Harvest Season

When removing this material, it can take several days if not weeks to do so. There are literally millions of grains of rice that must be harvested during the harvest season. As it begins to pile up, you can simply let it compost and then use it for that purpose. However, you might be better off converting this material into something else such as a burnable type of fuel. There is rice husk charcoal making machine called pyrolysis machines that can be used for this purpose. In fact, there are many that are calibrated to convert rice husks into materials like charcoal.

Where Can You Find Machines That Do This?

There are quite a few machines that you produce byproducts from rice husks. Some of those will include biofuel that is used in both commercial and industrial industries. If you are running heavy equipment, or if you have machines that utilize diesel fuel, this might be the best solution for your business. On the other hand, you may simply want to package up all of the biochar, sell it as charcoal, and start to make a profit. For all of these reasons, you may be interested in making this type of investment. At the very least, it can help you keep up with the large production of rice husks that you have every year.

What Is The Efficiency Level Of These Machines?

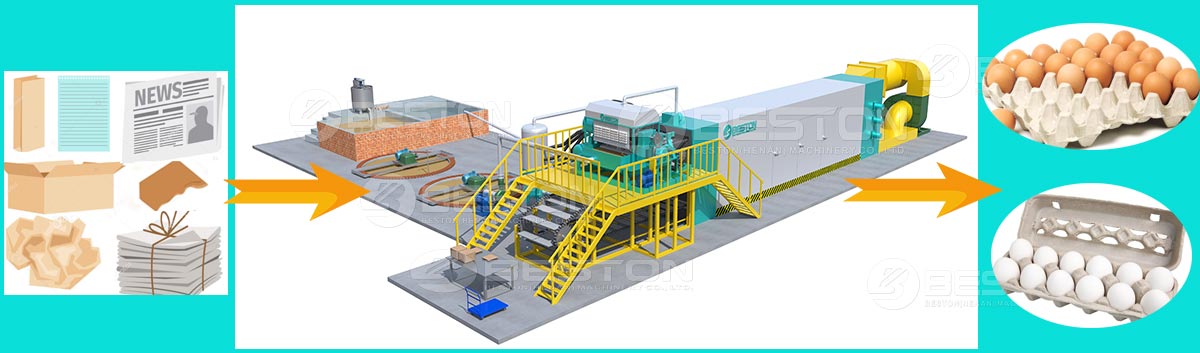

Efficiency levels of any of these machines is determined by looking at the specifications for these machines. You can look at them online, or you can request this information directly from the manufacturers. Many of these companies produce not only machines but entire plants, that are capable of working with rice husks. In time, you will locate a couple of businesses that will look promising. Consider their size, the size of the reactor chamber, and all of the other factors that will help you make this decision. In general, larger companies will need to have a biomass pyrolysis plant whereas others will need something smaller.

If you have not invested in a pyrolysis machine for your rice harvesting business yet, you may want to consider making this decision soon. As harvest season approaches, if you don’t know what to do with all of the tons of rice husks that will be produced, this is a viable solution. You can obtain one of the latest rice husk charcoal making machines for a very fair price. These are designed to be shipped and set up within days. It will assist any business, large or small, in disposing of rice husks that would otherwise go to waste. Start looking today for companies that produce these state-of-the-art machines. More: https://www.bestongroup.com/biochar-production-equipment/.