This is a question many small farmers, business inventors, and chicken farmers ask. After all, making paper egg trays is easy and can be done at home; as a way to increase production and help reduce expenses. As you probably know, paper egg trays were generally invented to transport fragile eggs to different stores. While at the store, they are stored in plastic egg trays mainly because of their strength. More information on how to make egg tray here.

How to Make Egg Trays

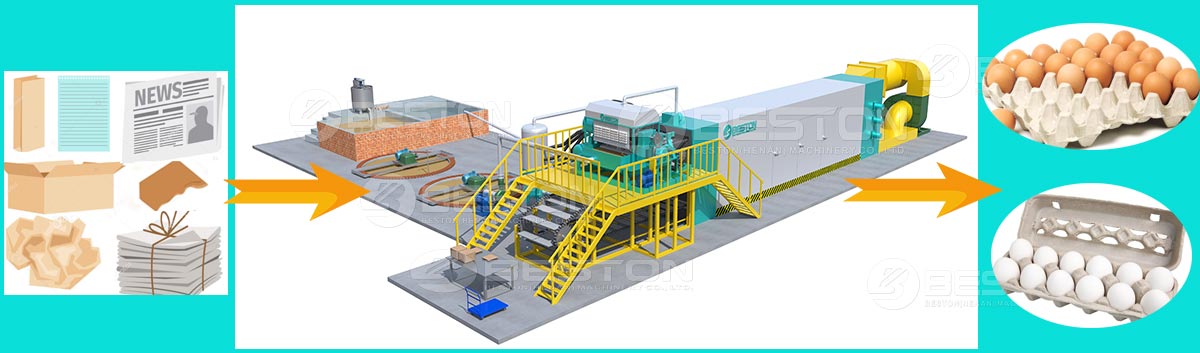

Egg tray production involves fort parts or steps. These are: –

• The making of raw material (Preparing the paper pulp)

• The formation section

• The drying section

• The packaging section

NOTE: For better results, it is wise to invest in an egg tray machine to make the whole process easy and safe for everyone.

Part 1: – The Making Of Raw Material

The first part of making a paper egg tray is preparing the raw material, which is a paper-based pulp. To get better results, it is wise to consider using a pulp-making machine. Pulp is made using all kinds of paper waste (cartons, old books, old newspapers, and others), warm water, salt, and glue.

NOTE: the pulp you make must have the right consistency to get tougher paper egg trays. Click here to know more: https://eggtraymakingmachine.net/pulp-molding-machine/.

A pulp-making machine includes a hydraulic pulpier, a pulp refiner, a pulp pump, and a water pump.

The second part of the making process is the formation section. This is a section where the formation of the tray is done. The pulp is transported to the forming machine using the pulp pump. In this section, some water is extracted and redirected back to the recycling tank. Clearly, this helps the environment.

It is important to note that the formation section is the backbone of the whole process or egg tray production line. A formation section machine includes a vacuum pump, air compressor, and molding plates (formation molds). Using different molding plates, you can design different kinds of items like cup holders, egg cartons, egg trays, fruit holders, fruit cartoons, and others. More information on the paper egg tray machine here.

Part 3: -The Drying Section

After the formation process, the trays must be dried. Remember, although the vacuum pump helps eliminate water, it does not remove all of it. This is why it must be dried further. However, this must be done in accordance with the material and the size. As you know, there are many drying options one may choose. However, the best one to choose will depend on several factors, such as the scale of the paper egg tray plant, investment costs, delivery, and others.

Build Brick Drying Line

Part 4: – Packaging

The final part of the whole process is packaging ready for transport or the market. This process is straightforward and does not need a lot of explanation.

Conclusion

The best thing about the egg tray production process is that you can add a pigment additive of your choice. This allows you to produce egg trays of all colors. However, when doing this, it is paramount to pay attention to the appropriate proportion. Why not visit the page: https://eggtraymakingmachine.net/manual-egg-tray-making-machine/.