There are so many machines that can produce pellets of many different types. They can do so automatically, producing millions of them in the span of a single day. These machines are designed to produce wood pellets that can be used with most pellet burning machines. You may also need one of these machines for fertilizer. Once you have found one of these companies, it will be very easy to decide which one is the one that you want. Getting the best price, however, is often very challenging. This is how you can obtain an affordable pellet making machine for sale on the web.

Pellet Making Machine

How Do These Produce Pellets?

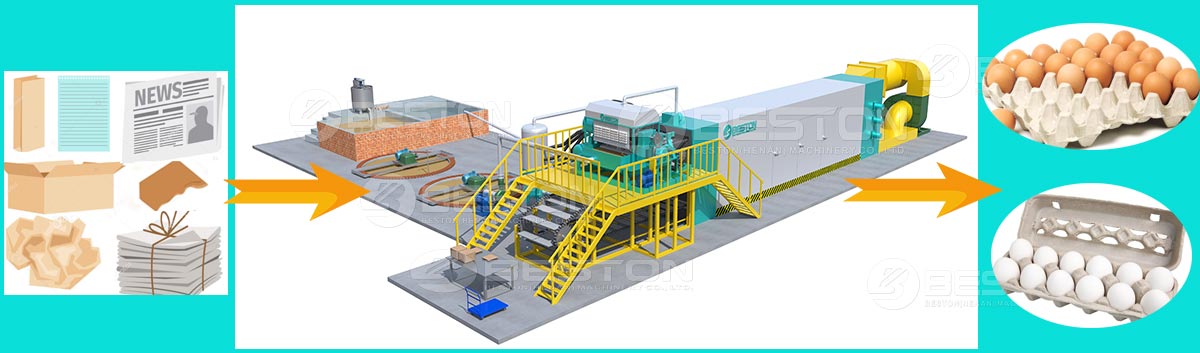

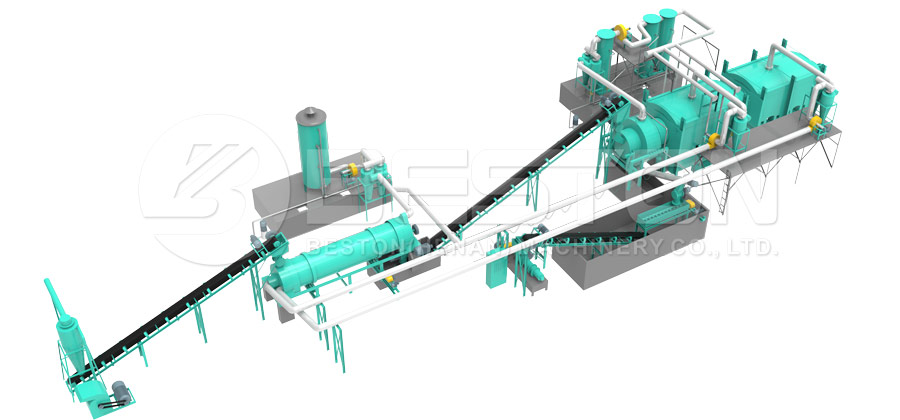

The machines are designed in a very specific and compact way that can receive the materials through a top funnel. The materials will then be rotated rapidly, forcing everything to what are called die holes, and they will subsequently solidify so that they can be processed, bagged, and ultimately sold. Whether you are converting wood based products into pellets, or if you are transitioning compost into fertilizer, you can do this with these machines. The key is to obtain one that is large enough to handle the volume of material you have access to, you will also be relatively affordable. More information on biomass pellet machine here.

Businesses that market these machines are relatively easy to locate. Overseas companies that specialize in industrial equipment will likely have several that you can buy. As you assess them, consider there output, size, and overall dimensions. There are those that are much larger that can out produce the smaller models. Keep in mind that there are different ones designated for various types of materials such as peanut shells, sawdust, and even branches and bark. Once that material has been shipped up into smaller components, you can then process it directly through these machines. The size of the pellets will range from a couple millimeters to up to 6 mm in diameter. Finally, publications online that are selling this type of wood pellet making machine will likely have several different choices that you can choose from.

Raw Materials to Make Pellets

How To Make Your Final Choice

Your final choice should be based upon three simple factors. Find out what type of raw materials can be used with the system. Second, ask if these are able to work continuously, and determine how automated the entire system is. Once you have this information, it will be very easy for you to make your decision on the best pellet mill that will work for your company.

To find the most affordable pellet making machine for sale, all it takes is a couple of phone calls. After you have located these companies on the web, contact them directly to get an estimate or a quote. Always ask questions about the types of materials that you will be able to use with their machines to ensure that it will be designed for your business. You will soon have one of the best sawdust pellet machine for sale on the market sold to you for a very fair price that can outperform any of the others on the market.