Charcoal making may not sound like a great way to spend your time or invest your cash but it is in fact one of the oldest tricks humans learned and profitable to a wide range of human endeavors. Charcoal maker machine create versatile solutions from a growing problem.

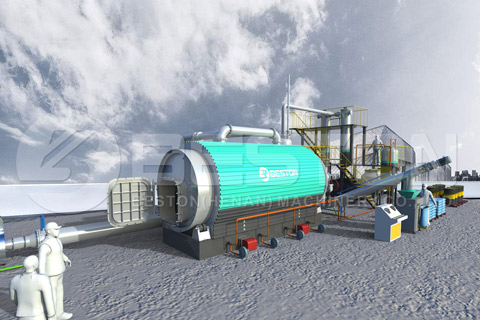

Charcoal Making Machine

The Abridged History of Charcoal

As early as 4000 BCE, Farmers in China and all across Asia were making charcoal by piling up wood, bamboo and other organic compounds and covering the pile with dirt and moss to keep out the air.

The fire would be lit and soon the entire heap of matter would be burning without the help of oxygen. After many hours, sometimes a full day, the materials inside would be transformed to charcoal suitable for lighting fires, purifying water and amending soils. Different type of organic matter will produce charcoal of all types. While wood charcoal had many advantages as a suitable fuel, other applications were soon found for charcoal products.

Charcoal can be found naturally in our environment, but because it is highly useful, humans soon learned the importance of manufacturing their own charcoal and even refining the charcoal making process. This is because all throughout history humans have relied on charcoal for its versatility and practicality in a number of human interests. Click here to know more: https://bestonpyrolysisplant.com/.

Humans first used charcoal as a source of fuel and its applications have not diminished in any way over the years. Charcoal provides a very clean smoke and even fragrant aromas of sourced from the right natural ingredients.

By the time the agricultural revolution had come about humans also learned that charcoal makes an excellent soil amendment and can greatly enhance the crop yield from tired soils. This was when the world first saw intentional charcoal making production although the charcoal making machine of the time were rudimentary.

Today charcoal still holds a place of great importance in all manner of industries. Charcoal is still an important soil amendment for feeding the world’s growing populations. Super high grade charcoals, such as coconut shell charcoal, can be activated with a positive charge and are crucial to purifying water and removing toxins and harmful compounds from potable and waste water supplies.

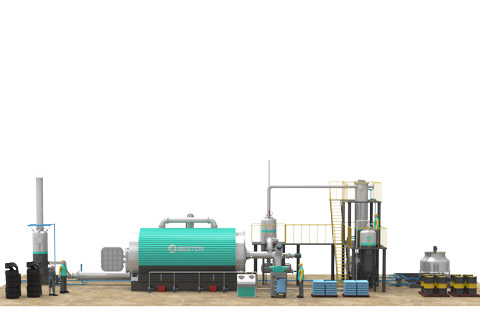

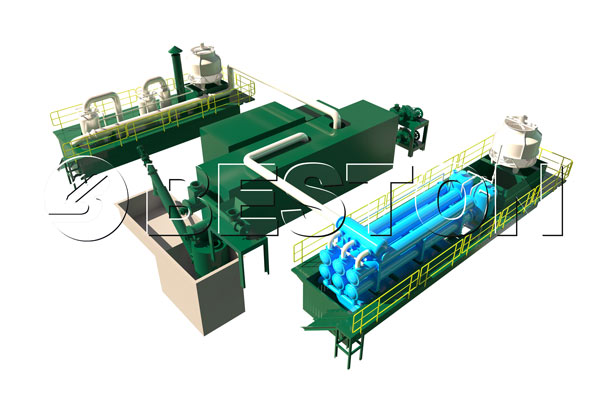

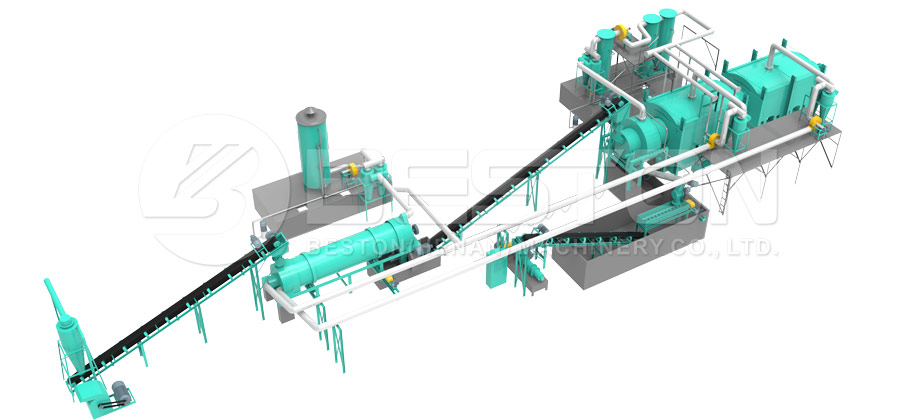

Modern Charcoal Making Machines

Charcoal can be made from just about any type of organic matter and is therefore a suitable way or transforming a large quantity of human waste into something useful and practical. Some of the materials that can be transformed into charcoal include, (organic) waste from carpentry shops and construction projects, garden refuse and tree clippings from city maintenances and human animal waste compounds.

To accomplish this using rudimentary methods would quickly accelerate many environmental catastrophes as the old ways released too much CO2 into the atmosphere. On the other hand sophisticated charcoal maker machine can transform large amounts of organic waste into high-quality charcoal without increasing pollution levels and minimizing the issues with waste management. See the blog: http://beston.bravesites.com/.

This is where cutting edge design meets ancient technology to produce a solution to a few human needs. First, biochar is a profitable solution to an ugly problem. Second, biochar can provide a solution to the needs for alternative and sustainable energy sources and, third, biochar is a great way to improve crop soils and feed a hungry populace.