We are focused on recycling more than ever before. When people think of recycling, they are typically considering materials like aluminum, glass, or even cardboard. However, recycling can also play a role in the production of burnable fuels. These fuels may include biofuel and charcoal. These materials are made because of a process called pyrolysis. There is pyrolysis machine that can aid in the conversion of these materials into charcoal and bio oil. These are very lucrative materials that you can produce very easily as long as you have access to vast quantities of biomass at your disposal.

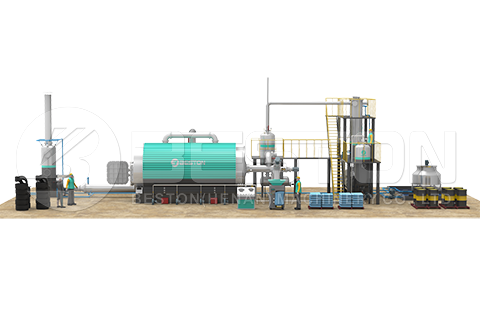

Beston Pyrolysis Plant – Reactor

How Exactly Does A Pyrolysis Machine Operate?

These machines are designed to be easy to use. The main component of any of these machines is the chamber. It is also called a reactor, a closed area that can remove oxygen from the interior and also raise the temperature to several hundred degrees inside. The reason for these machines is to take biomass which can be converted into charcoal and biofuel once the process is over. The biofuel is typically in the form of a gas that will contents. The solid residue from this process, in the absence of combustion, provide you with the charcoal that you can use and sell. Do you know pyrolysis machine cost? Contact Beston.

Will You Be Able To Find One Near You?

Finding one of these companies will be relatively easy. It is because of the commonality of these machines in our daily world. The conversion of biomass has become more widespread, happening in multiple countries. To find a company that sells them, simply search for a biomass conversion machine. You can also search for a pyrolysis machine instead. This will direct you to websites where they are selling these at very reasonable prices, helping you to get one that is affordable. Read this tyre to oil project report.

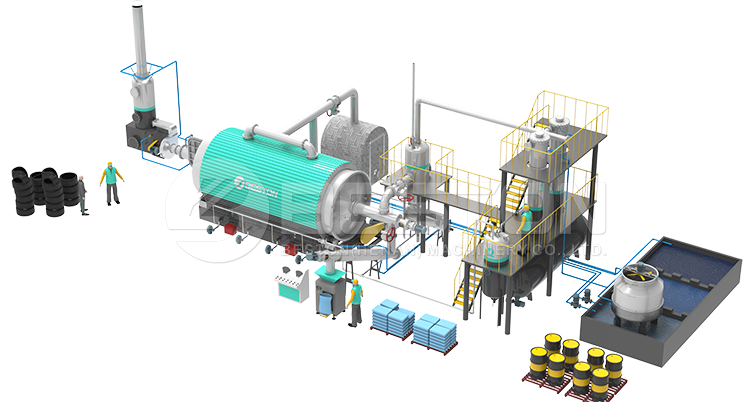

Beston Pyrolysis Machine Project

How Often Will You Use These Machines?

These machines are often used on a daily basis by most companies. They are often purchased by businesses that understand how lucrative this industry can be. For those that have never sold bio oil, biofuel, or charcoal before, you may be astounded at how easily you can market these products. In certain countries, this represents the materials that they need to keep their house warm day or night. Therefore, depending upon the country you are in, and the demand for these products, you can choose the best pyrolysis machine for your needs. When you have demand for this machine, click Beston Group China to contact a reliable manufacturer directly.

It is so important to utilize a pyrolysis plant or machine if you have access to large quantities of biomass at your facility. You could be producing these on your own, or you may get access to large quantities of sawdust, sewage waste, and other materials that can work with this process. Many of the companies that produce them will have multiple units in stock. Once you have placed your order, you will be able to take delivery of this machine that can convert biomass into burnable if you through the pyrolysis process. In no time at all, you will understand why so many businesses today are investing in this equipment which can produce burnable fuels.