When you produce products that are fragile, they need to be properly protected. Of any product that you can produce, eggs are certainly at the top of the list when it comes to fragility. When they are packaged and shipped, they need to remain intact the entire way. Any damage to the outer shell can lead to a loss in product sales. Egg trays are one of the best ways to ensure their safety. If properly created, these trains can serve as not only a form of protection, but a way of packaging these goods. You can find businesses that are constantly manufacturing different industrial products, one of which will be machines that can produce trays designed for eggs.

Can This Be Automated?

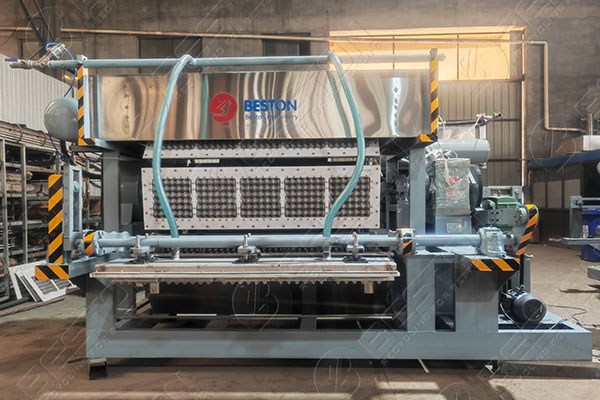

The simple answer to this question is yes. In fact, the vast majority of machines that are designed to produce trays for eggs tend to be fully automated by those that create them. The egg tray machine manufacturers understand it is important to accelerate the process of creating as many trays as possible. However, they are also aware that the quality of the trays is just as important. Business is located in various areas of the world have become experts in this industry. Once you have found a couple of them, you will want to get some vital information.

What Information Will You Need?

The information that you will request will include the following. It will be a price list, a list of the capabilities of each machine, and a schedule for when it can be shipped. If you have not ordered one before, or if you do not have an account with the industrial packaging machines, it may take a few extra days to get everything in order. Prior to placing an order for any of these machines, it’s imperative that you look at the specifications for each one. Most of them will be similar, yet there will be some companies that will produce the best units available.

How To Get The Best Machines For Less

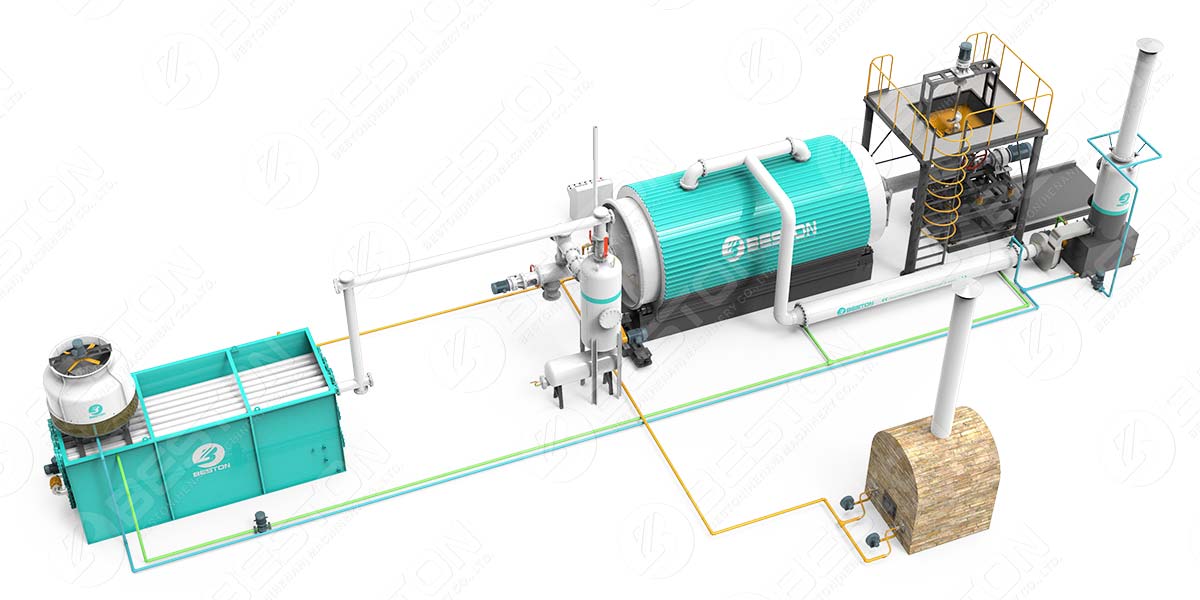

Top rated machines from the most reliable companies tend to come at a cost. You may not be able to save as much money as when using the cheapest businesses in the industry, but you will get a high quality machine instead. Egg tray production is also very straightforward. It involves the use of heaters, paper pulp machines, and a conveyor belt system that all work in tandem. You need to pay special attention to how the machine works and the volume of trays that can be produced on an hourly basis: https://pulpmouldingmachines.com/small-egg-tray-making-machine/.

The manufacturing of any type of tray does involve the use of paper pulp if you are looking for proper packaging. The production of this packaging can be streamlined significantly when using a fully automated system. The cost of these units, and how long they will take to arrive, or things that you will discuss with each manufacturer. If your primary objective this year is to invest in a brand-new egg tray machine for sale that will produce egg trays for you, you now have the basic knowledge for finding the most reliable company.