In the labyrinth of urban challenges, where carbon emissions loom large, a beacon of hope emerges – biochar production equipment. This cutting-edge technology not only tackles the carbon conundrum but does so with finesse, aligning urban spaces with the trajectory of carbon neutrality.

The Essence of Biochar Production Equipment

Biochar production equipment constitutes the linchpin of a transformative process, harnessing the power of pyrolysis. Through this method, organic biomass undergoes thermal degradation, birthing a carbon-rich substance known as biochar. The complexity lies in the intricacies of the pyrolysis process, where controlled temperatures and meticulous biomass conversion contribute to the production of high-quality biochar.

Urban areas, often the epicenter of carbon emissions, can benefit significantly from embracing this technology. The carbon content of biochar becomes a reservoir, capable of sequestering carbon and mitigating the urban carbon footprint.

Carbon Sequestration Dynamics

Delving into the technicalities, the carbon sequestration potential of biochar becomes apparent. Its introduction into the soil initiates a sophisticated dance between carbon molecules, orchestrating a symphony of stability. This process, driven by the porous structure of biochar, ensures long-term carbon sequestration, surpassing the capabilities of conventional methods.

Comparisons with traditional strategies, such as afforestation and carbon capture and storage (CCS) technologies, underscore the prowess of biochar. The dynamic interplay of carbon sequestration and soil enhancement places biochar production equipment at the forefront of urban sustainability initiatives.

Fertility Amplification and Nutrient Alchemy

Beyond its carbon sequestration capabilities, biochar orchestrates a transformative ballet in the soil. Its introduction enhances soil structure, fostering a delicate balance of porosity and water retention. This, in turn, becomes a catalyst for nutrient availability, unlocking a realm of possibilities for urban agriculture.

In the tapestry of urban landscapes, biochar production equipment facilitates the rejuvenation of contaminated soils. Through its unique chemical composition and microbiome-enhancing qualities, biochar becomes an ally in the quest for sustainable urban agriculture and ecological restoration.

Integration into Urban Infrastructure

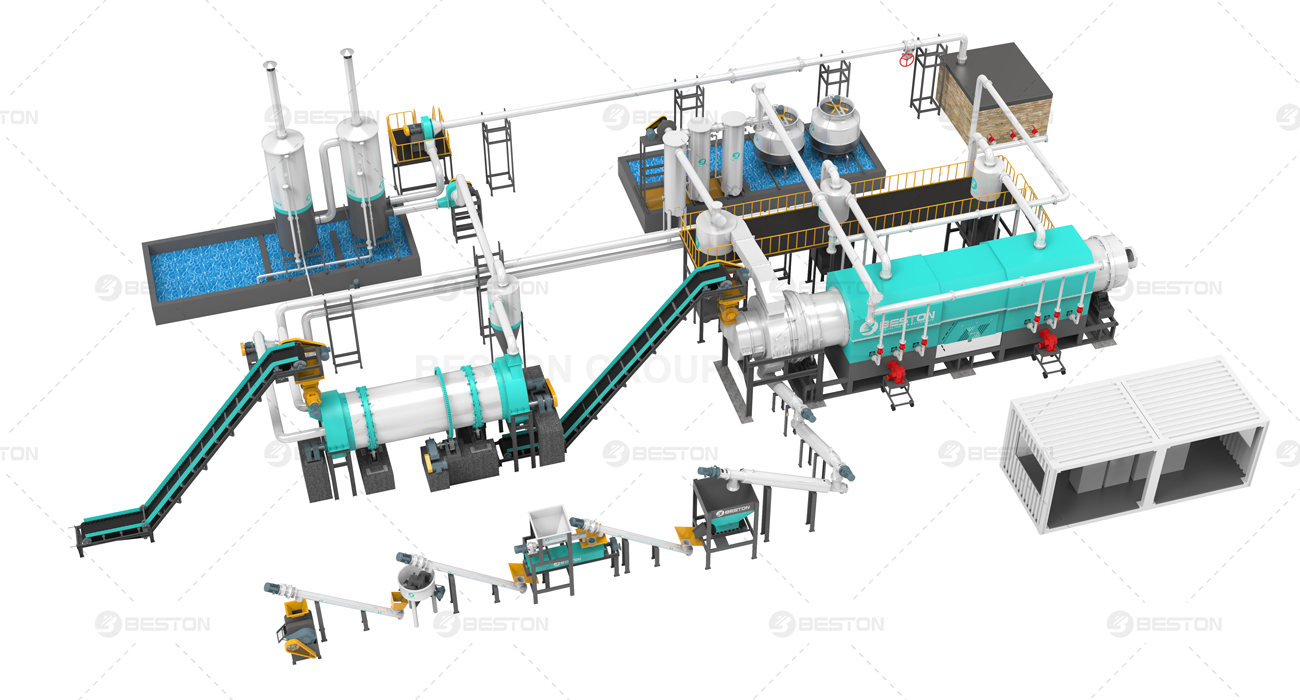

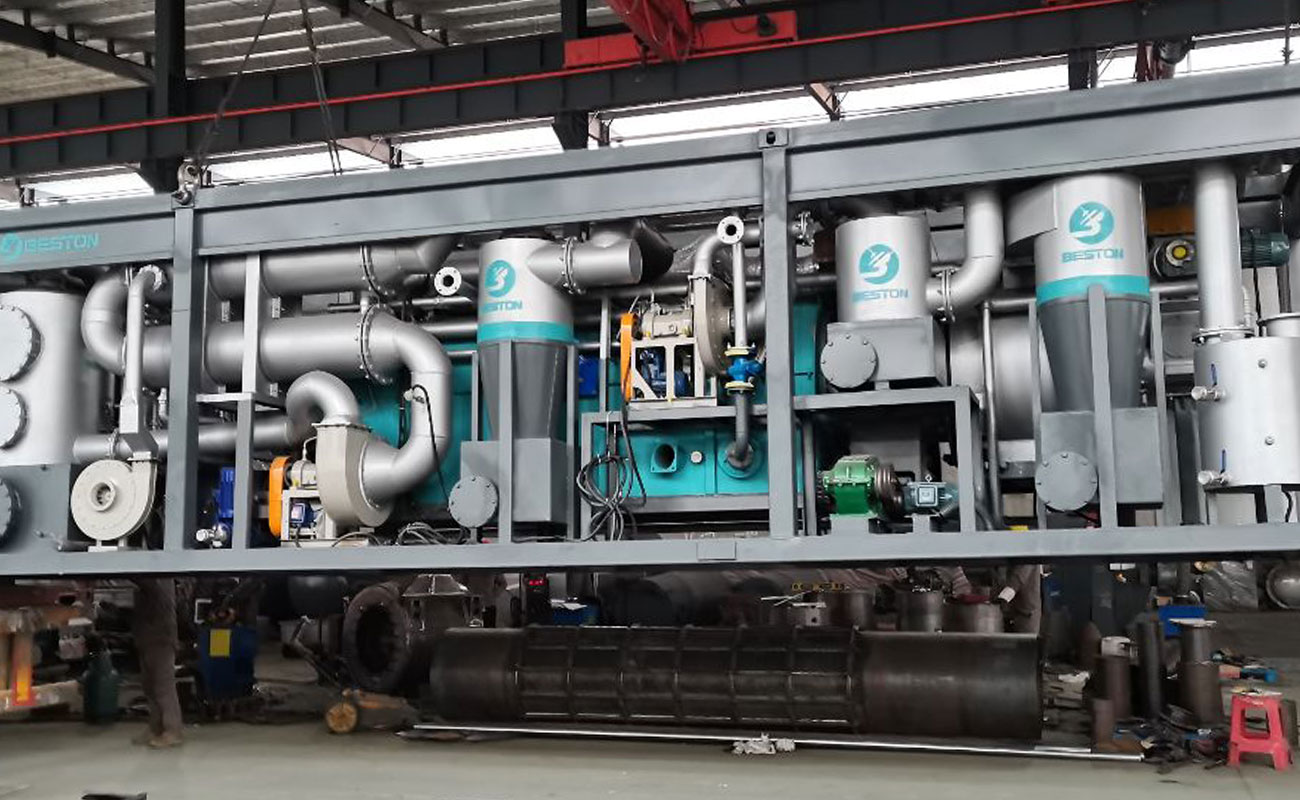

Implementing biochar production equipment, especially mobile biochar machine in the urban milieu requires a careful choreography of design considerations. These include spatial efficiency, scalability, and odor control. The technical blueprint of these facilities ensures not only environmental efficacy but also seamless integration into the urban fabric.

Community involvement stands as a pivotal element in this narrative. Education initiatives, collaborative endeavors with local governments, and businesses weave a narrative of shared responsibility. The result is a symbiotic relationship where biochar production equipment becomes a communal asset, driving urban spaces towards sustainability.

Economic Dynamics and Incentives

In the realm of urban planning, the economic viability of sustainable initiatives holds sway. Biochar production equipment, despite initial setup and operational costs, emerges as a strategic investment. Its long-term benefits for urban communities transcend monetary considerations, encompassing environmental health and resilience. Speaking of this, you need to find a reliable equipment manufacturer, here we recommend Beston Group Co., Ltd.

Government incentives play a crucial role in catalyzing the adoption of biochar production equipment. Tax credits and subsidies become pivotal drivers, aligning economic interests with ecological imperatives. This synergy positions biochar as a cornerstone in the edifice of urban sustainability.

Conclusion: Paving the Path to Urban Carbon Neutrality

In the symphony of urban development, where carbon emissions echo as a dissonant note, biochar making machine emerges as a harmonious solution. Its technical prowess, coupled with the ability to sequester carbon, enhance soil fertility, and integrate seamlessly into urban infrastructure, positions biochar as a beacon of hope for carbon neutrality.

As urban landscapes evolve, the integration of biochar production equipment becomes more than a technological feat; it becomes a testament to the resilience of sustainable practices. In the grand narrative of urban sustainability, where every decision echoes through the corridors of the future, biochar stands as a transformative force, paving the path to a carbon-neutral urban tomorrow.