Pyrolysis is a process that involves the thermal decomposition of organic materials in the absence of oxygen. This technology has gained significant attention worldwide as a means to convert various waste materials into valuable resources such as biochar, bio-oil, and syngas. Small scale pyrolysis equipment offers a cost-effective and efficient solution for individuals or small businesses interested in harnessing the potential of pyrolysis technology. In this post, we will explore the benefits, applications, and considerations of small scale pyrolysis equipment.

Understanding Pyrolysis:

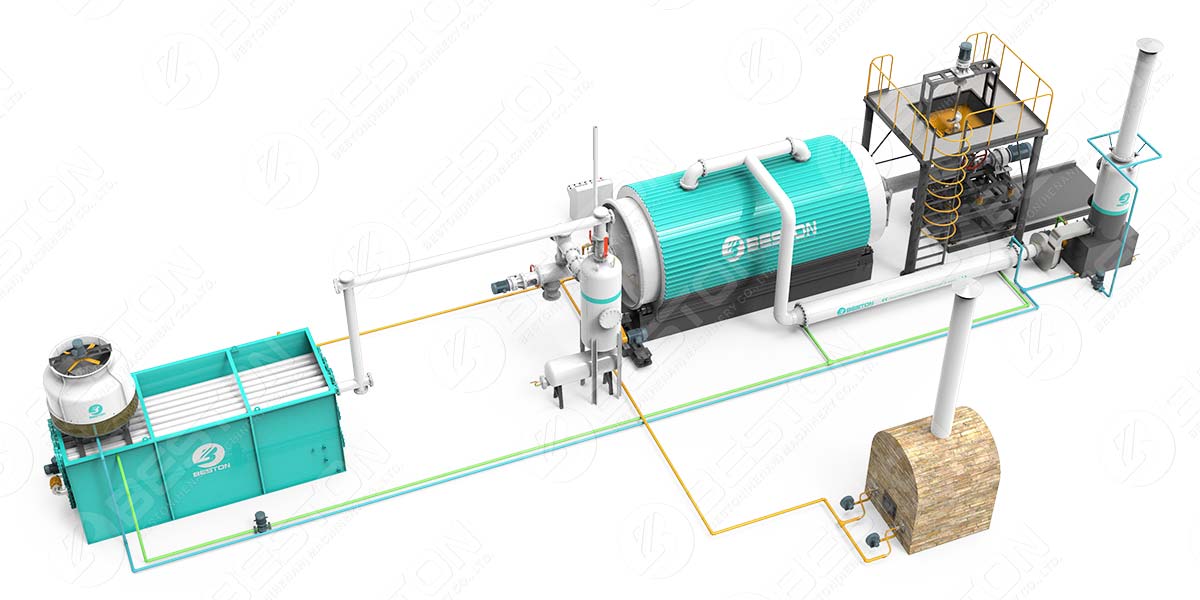

Pyrolysis is a thermochemical process that breaks down organic materials at high temperatures, typically ranging from 400-800 degrees Celsius, in the absence of oxygen. The absence of oxygen prevents combustion and results in the formation of valuable byproducts. The process produces three main products:

a) Biochar: A solid carbon-rich material with excellent soil amendment properties. It improves soil fertility, water retention, and nutrient absorption.

b) Bio-oil: Also known as pyrolysis oil, it is a dark brown liquid that can be further upgraded into transportation fuels or used as a heating fuel.

c) Syngas: A mixture of hydrogen, carbon monoxide, methane, and other gases that can be utilized as a source of energy in various applications.

Benefits of Small Scale Pyrolysis Equipment:

a) Waste Management Solution: Small scale pyrolysis equipment provides an effective means to address waste management challenges. It can process a wide range of organic waste materials, including biomass, agricultural residues, plastic waste, rubber, and more.

b) Resource Recovery: Through pyrolysis, valuable resources like biochar, bio-oil, and syngas are generated. These products have numerous applications, ranging from soil improvement and energy production to chemical synthesis.

c) Energy Efficiency: Small scale pyrolysis equipment utilizes the heat generated during the process to sustain its own energy requirements. It operates as a self-sustaining system, minimizing external energy inputs.

d) Environmental Impact: Waste tyre pyrolysis machine offers an environmentally friendly waste management solution by reducing landfill waste, preventing harmful emissions that occur during conventional waste disposal methods, and promoting the circular economy.

e) Economic Opportunities: Small scale pyrolysis equipment enables individuals and small businesses to explore entrepreneurial opportunities. By converting waste into valuable resources, it opens doors for revenue generation through product sales or value-added applications.

Applications of Small Scale Pyrolysis Equipment:

a) Agriculture and Horticulture: Biochar produced from pyrolysis can be used as a soil amendment to enhance crop productivity, water retention, and nutrient availability. It improves soil structure and reduces the need for synthetic fertilizers.

b) Energy Generation: The syngas produced during pyrolysis can be used as a fuel for electricity generation or heat applications, replacing traditional fossil fuels. Bio-oil can also be utilized as a renewable heating fuel in boilers or converted into transportation fuels.

c) Waste-to-Value Conversion: Small scale pyrolysis equipment allows the conversion of various waste materials into valuable resources. Plastic waste can be transformed into high-quality, carbon-rich biochar, reducing plastic pollution and providing an alternative to landfills or incineration.

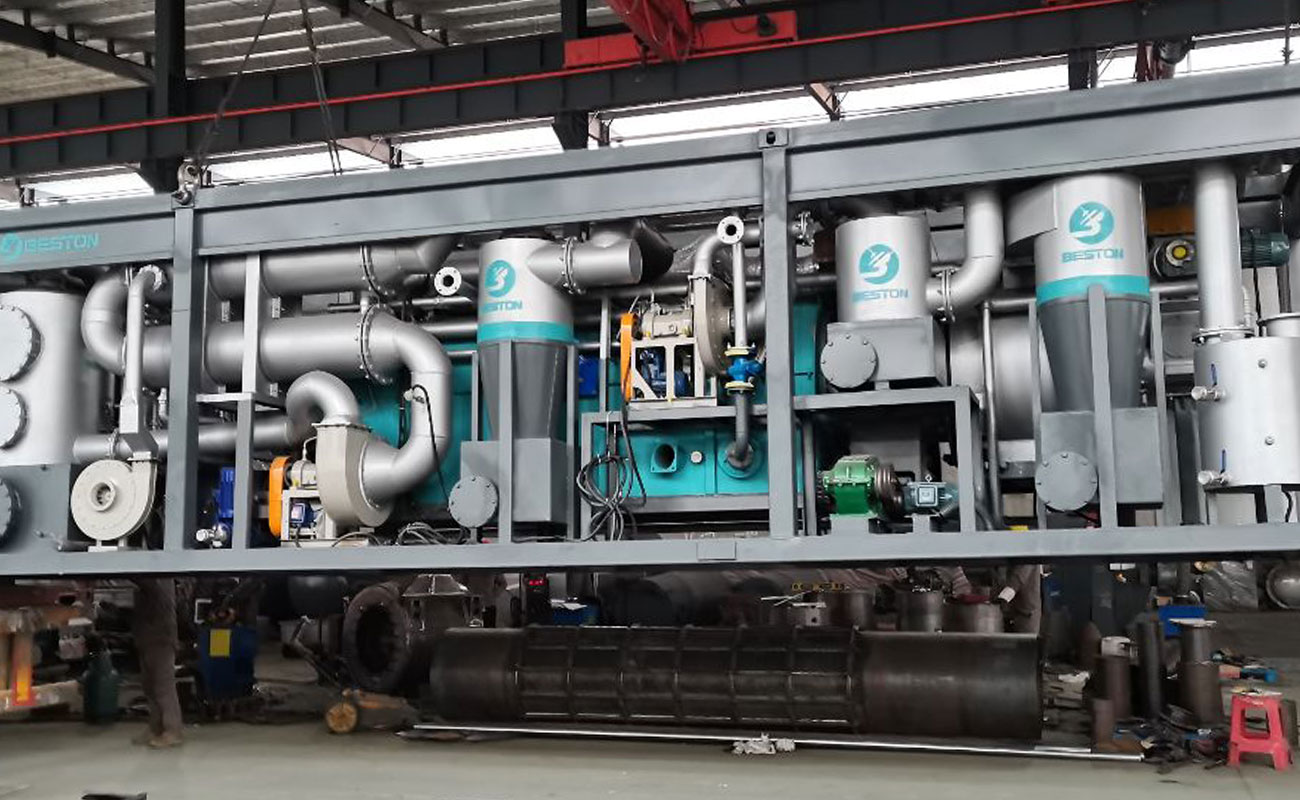

d) Industrial Applications: Pyrolysis products find applications in chemical processes, such as producing activated carbon, carbon black, and specialty chemicals. These materials are essential in industries such as water treatment, pharmaceuticals, and cosmetics. View some type of this machine for your reference: https://www.bestongroup.com/thermal-desorption-unit/.

Considerations for Small Scale Pyrolysis Equipment:

a) Feedstock Selection: Different feedstocks have varying compositions and properties, influencing the yield and quality of pyrolysis products. The applications of small scale pyrolysis equipment span across agriculture, energy generation, waste-to-value conversion, and industrial processes. However, there are important considerations to keep in mind when utilizing this technology.

One crucial factor is the selection of feedstock. Different feedstocks have varying compositions and properties, which can impact the yield and quality of the pyrolysis products. It’s essential to choose appropriate feedstocks based on their availability, characteristics, and intended applications. Conducting thorough research and testing is recommended to determine the most suitable feedstock for your specific needs.

Another consideration is the capacity and scalability of the small scale pyrolysis equipment. Evaluate the volume of waste you intend to process and select equipment that aligns with your requirements. Additionally, consider the potential for future expansion or increased demand. Investing in scalable equipment ensures flexibility and adaptability as your business grows.

Before investing in small scale pyrolysis equipment, conduct market research to identify potential customers or end-users for the produced biochar, bio-oil, or syngas. Evaluate the demand, pricing, and competition to assess the economic viability of your venture. Understanding the market dynamics will help you make informed decisions and develop effective marketing strategies.

In conclusion, small scale pyrolysis equipment presents an attractive opportunity for individuals and small businesses to convert waste materials into valuable resources. Its benefits include waste management, resource recovery, energy efficiency, and economic opportunities. By selecting suitable feedstocks, ensuring equipment capacity and scalability, implementing safety measures, complying with regulations, and conducting thorough market research, you can maximize the potential of small scale pyrolysis equipment in a sustainable and profitable manner. Embracing this technology contributes to a circular economy, environmental conservation, and the efficient utilization of our resources.