The fascinating world of pyrolytic carbon has captured the attention of scientists and engineers alike. Its unique combination of physical and chemical properties opens doors to a multitude of applications, ranging from environmental remediation to advanced materials. The journey from understanding the microscopic architecture to harnessing macroscopic functionalities is both intricate and inspiring.

Understanding the Microstructure

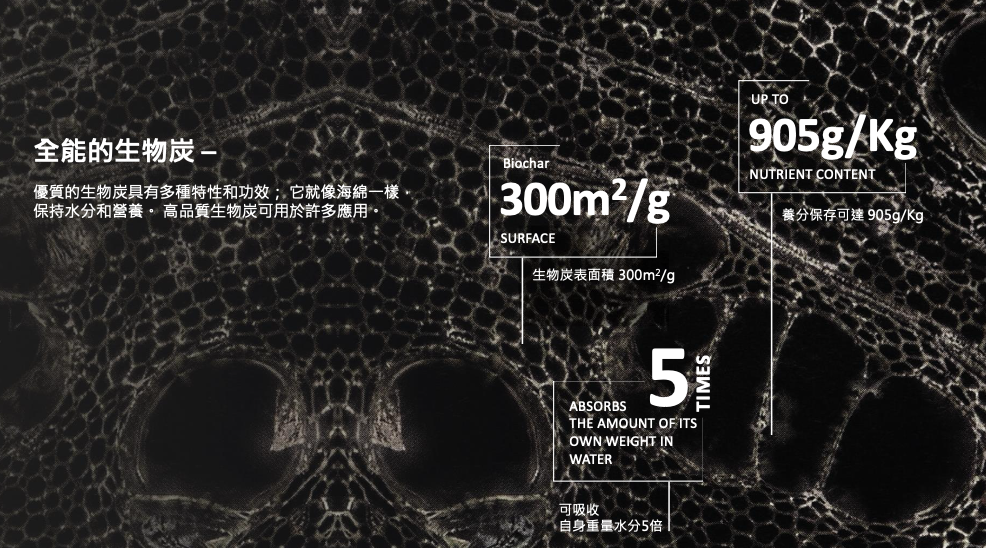

At the core of pyrolytic carbon’s behavior lies its microstructure. Characterized by an extensive network of pores, these tiny cavities govern the material’s adsorption capacity, mechanical strength, and thermal stability. Techniques like scanning electron microscopy (SEM) and X-ray diffraction (XRD) are frequently employed to reveal these complex internal geometries.

Scientists have observed that the pore distribution can vary significantly depending on the source material and the pyrolysis conditions. For instance, the use of biochar pyrolysis equipment allows precise control over temperature and heating rates, directly influencing pore size and volume. Smaller micropores typically enhance adsorption properties, while larger mesopores improve fluid transport and structural stability.

From Micro to Macro: Translating Structure into Performance

The microstructural characteristics of pyrolytic carbon are not just academic curiosities—they translate directly into observable macroscopic properties. A highly porous structure, for example, significantly increases surface area, making the material highly effective in filtration, catalysis, and soil amendment. Similarly, mechanical properties such as compressive strength are influenced by how evenly the pores are distributed within the carbon matrix.

Advanced biochar machines allow manufacturers to produce carbon with consistent properties, which is crucial for industrial applications. The ability to fine-tune these properties ensures that the material performs reliably, whether it is used in environmental cleanup or energy storage devices.

The Role of Biomass Sources

Different biomass feedstocks contribute unique characteristics to the resulting carbon. Hardwoods, crop residues, and even certain agricultural by-products produce carbon with varying pore distributions and chemical functionalities. Employing modern biomass pyrolysis equipment helps convert these diverse sources into uniform, high-quality carbon suitable for specific applications.

The chemical composition of the starting material also affects the carbon’s ability to adsorb pollutants or store energy. Nitrogen-rich feedstocks, for instance, can enhance adsorption of certain gases, while lignin-rich sources improve thermal stability. Understanding these nuances allows researchers to design carbon materials that meet precise performance requirements.

Applications Driven by Porosity

One of the most compelling aspects of pyrolytic carbon is its versatility. In agriculture, porous carbon acts as a soil amendment, improving water retention and nutrient availability. In environmental engineering, it serves as an effective adsorbent for heavy metals and organic pollutants. The key to these applications lies in controlling pore size distribution and surface chemistry.

Porous carbon also finds applications in energy storage. Electrodes for supercapacitors and batteries benefit from the high surface area and interconnected pore networks, which facilitate ion transport and increase storage capacity. By optimizing pyrolysis parameters, manufacturers can produce carbon materials that maximize these functional benefits.

Future Perspectives

The exploration of pyrolytic carbon is far from over. As analytical techniques improve and production methods become more sophisticated, our understanding of the link between microstructure and macroscopic performance will deepen. This knowledge will drive the development of tailored carbon materials that can meet the specific needs of diverse industries, from environmental protection to renewable energy.

With continued investment in technology and research, the potential applications of porous carbon are virtually limitless. Whether it’s capturing carbon dioxide, purifying water, or enhancing energy storage, this material’s unique properties ensure it will remain a focus of scientific and industrial interest for years to come. More in Beston Group.

In conclusion, the world of pyrolytic carbon offers a remarkable example of how microscopic structures can dictate macroscopic functionality. Through careful study and technological innovation, the material continues to demonstrate its versatility and value across a wide range of applications.