A lot of businessmen are interested in waste pyrolysis plant. Better profits and cheap raw materials are the prime reasons behind the growing popularity of this plant. However, assessing the cost-benefit ratio is paramount before you head out and buy this cutting-edge equipment. In this respect, the pyrolysis plant cost plays an important part.

Many businesses buy the plant without considering various parameters that add up to the cost. Most of them simply look at the markup price of the machine. If the price fits within their budget, they choose the machine. However, that’s a wrong perception and bad idea. You need to think beyond the listed price of the equipment.

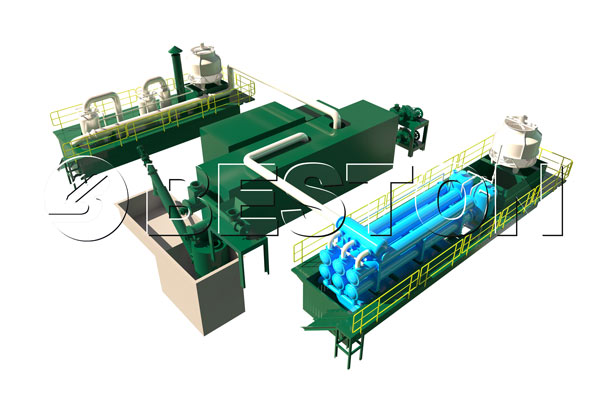

Pyrolysis Equipment to South Africa

Pyrolysis Plant Cost Analysis

When it comes to estimating the cost of the pyrolysis plant, it’s important to take into account various parameters that go into the cost of the equipment. For instance, the original price of the equipment is the starting point.

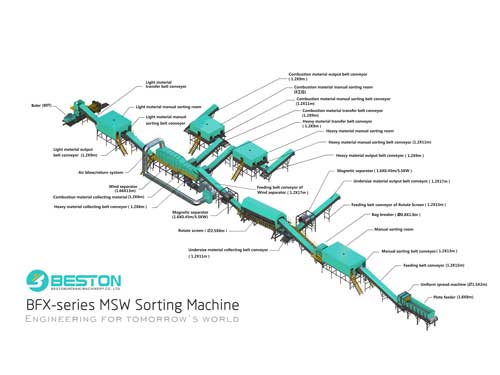

Of course, you would like to compare the price of the machine offered by numerous brands, such as Beston Group, to make the best choice. While you might be happy to choose a low-priced machine after making thorough assessments, you could finish up with the most costly machine in the long run. How?

The truth is the original price is only a fraction of the cost. Although it accounts for a major portion of the cost, it doesn’t constitute the cost alone. Other factors need equal consideration and should be added to the original cost.

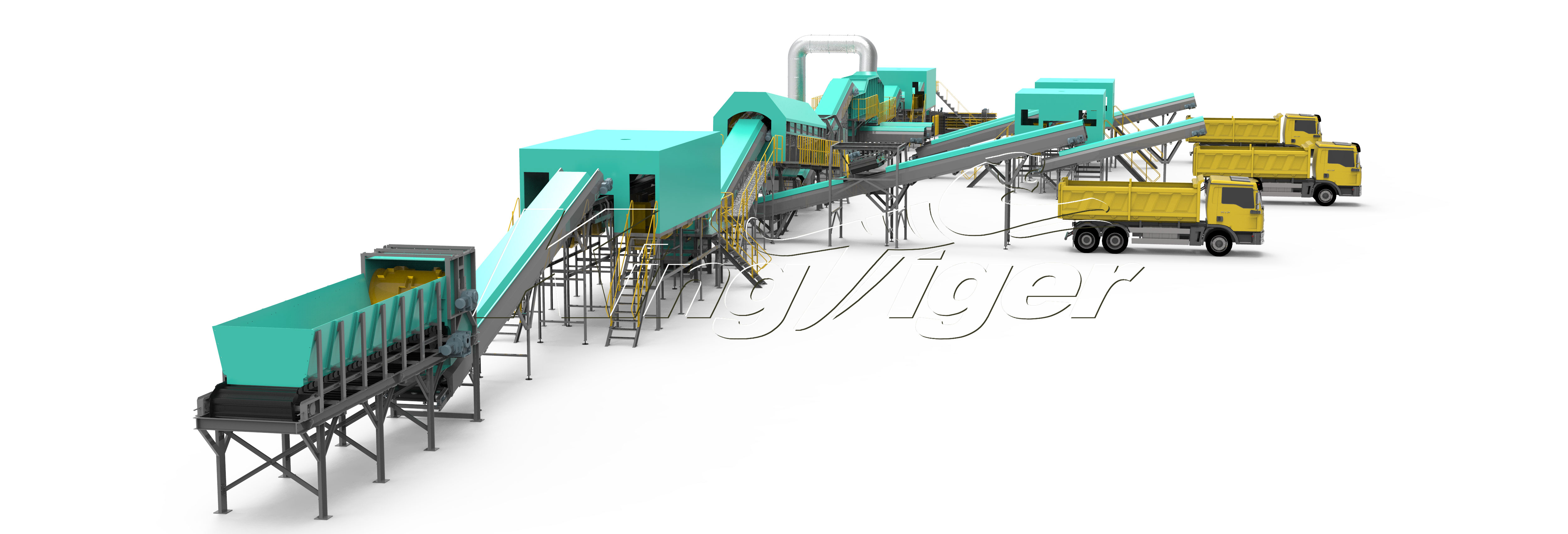

Tire Recycling Plant in Indonesia

This was just a small portion of the cost that was overlooked in the purchase. Imagine if you miss out many other things that will increase the cost substantially. So what to look for and what to consider when you’re estimating the cost? Let’s check it out below.

Business Plan for Pyrolysis Plant

To do away with your worries related to the cost, the business plan for the plant comes into action. It takes into consideration various parameters that will affect your cost and hurt your finances.

Besides the original machine price and installation, you should consider after sales services. Always check out reputed vendors such as Beston Machinery that offers free after sales services. So, what are after sales services and how they add up to the cost? After sales services are professional consultancy advice on troubleshooting or repairing the machine. Here is a picture of Beston engineers installing tire pyrolysis plant in the UK.

Engineers in the UK

When you install a new plant, you’ll definitely need professional advice and consultancy services. It’s likely that the new machine isn’t working efficiently and consumes too much energy. Perhaps, the plant is making too much noise during production. Any such issue warrants professional help. However, hiring the expertise of a professional could be a pricey affair, increasing your cost.

By buying a machine from a vendor that provides free after-sales services, you can save yourself from getting ripped off on professional advice. A company like Beston offers free of cost after sales services to the fullest satisfaction of the buyer. In fact, their deal isn’t finalized until your machine works efficiently and the production cycle is seamless.

Durability and maintenance of the machine are other factors that will increase your cost in the long run. If the plant wears out or breaks after a couple of years, you may need to replace it with a new one. However, that can disturb your production cycle and hurt your finances. Also, your profitability ratio will take a big hit if the machine needs regular maintenance on a continual basis. It’s best to assess these points and ensure that the machine is highly durable and will last longer without requiring too much maintenance.

Bottom line

Investing in the waste recycling machine could yield higher profits provided you pay attention to the pyrolysis plant cost properly. Just be sure you check all the above points when estimating the cost of the plant. With useful info in your hands, you can easily make the right decision and land a reasonable deal to make big profits with this sophisticated plant.