The rapid accumulation of plastic waste has become a critical environmental challenge globally. But with the right technology, plastic waste can be transformed into valuable resources. Beston Group Co., Ltd. is at the forefront of this revolution, offering cutting-edge pyrolysis machines for sale and thermal desorption plants designed to address waste problems while generating useful byproducts, such as fuel. In this article, we’ll explore how these technologies work together to turn plastic into fuel and contribute to a sustainable future.

1. The Growing Demand for Plastic Waste Solutions

Plastic waste is pervasive, and its environmental impact is undeniable. Plastics, being non-biodegradable, persist in landfills and oceans, harming ecosystems and contributing to pollution. This has driven the need for innovative waste management solutions. Enter Beston Group Co., Ltd., a leading manufacturer that specializes in providing advanced pyrolysis and thermal desorption technologies to handle waste plastics, tires, and other materials.

2. How Pyrolysis Turns Plastic into Fuel

Pyrolysis machines have gained significant attention for their ability to convert plastic waste into fuel. The process involves heating plastic waste in an oxygen-free environment, which breaks down the polymers into smaller hydrocarbons. These hydrocarbons can then be processed into different forms of fuel, including pyrolysis oil, carbon black, and syngas.

Here’s how it works:

- Step 1: Feeding the plastic – Plastic waste is fed into the pyrolysis machine, where it’s heated to high temperatures (usually between 350°C and 500°C).

- Step 2: Thermal decomposition – Without oxygen, the plastic breaks down into gases and liquids.

- Step 3: Collection of byproducts – The resultant gases are cooled and condensed into oil, while any remaining solid residues, such as carbon black, are collected. The syngas generated can also be reused as a fuel source to power the system.

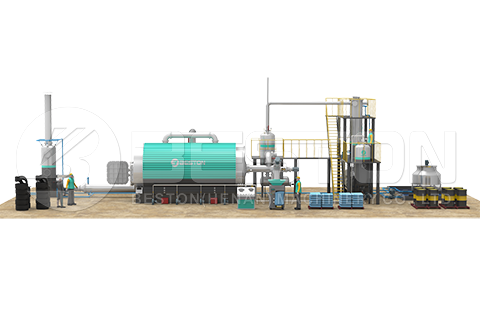

Beston’s pyrolysis machines for sale are designed with efficiency and sustainability in mind. These machines offer a reliable way to transform unwanted plastic into a useful commodity, reducing reliance on fossil fuels and addressing waste management problems simultaneously.

3. The Role of Thermal Desorption Plants

While pyrolysis focuses on the chemical breakdown of waste into fuel, thermal desorption plant handles more complex waste materials, such as oil sludge and contaminated soil. This process uses heat to separate organic contaminants (such as hydrocarbons) from solid waste. The recovered contaminants are then refined, making the process particularly valuable for hazardous waste management.

Beston’s thermal desorption plants utilize indirect heating methods to remove moisture and separate hydrocarbons from waste, rendering the leftover materials safe for disposal or further use. When paired with pyrolysis technology, these plants offer a comprehensive waste management solution, ensuring that nothing is wasted.

4. Combining Pyrolysis and Thermal Desorption for Maximum Efficiency

When plastic waste is processed in a pyrolysis machine, the oil and gas produced can be refined and utilized as alternative fuels, thereby reducing the demand for petroleum-based energy sources. On the other hand, thermal desorption can handle more challenging waste types, enhancing the overall effectiveness of waste management efforts. Together, these technologies complement each other by maximizing the recovery of valuable resources while minimizing environmental harm.

For companies looking to adopt sustainable practices, Beston Group Co., Ltd. provides the perfect blend of innovation and practicality. By integrating both pyrolysis and thermal desorption, businesses can not only reduce their environmental impact but also generate profits from waste.

5. Why Beston Group Co., Ltd. Stands Out

Beston Group’s commitment to environmental sustainability is evident through their technological advancements. Whether you’re in need of a pyrolysis machine for sale to handle plastic waste or a thermal desorption plant to deal with oil sludge and contaminated soils, Beston offers state-of-the-art equipment that meets modern waste management challenges head-on.

Their solutions are designed with efficiency, cost-effectiveness, and eco-friendliness in mind, ensuring that clients can operate sustainable, profitable businesses while tackling global waste issues.

6. Turning Plastic into Fuel: A Game-Changer for Waste Management

One of the biggest advantages of turning plastic into fuel through pyrolysis is that it not only mitigates the plastic waste problem but also provides an alternative energy source. The pyrolysis oil produced can be used in industrial heating, as a precursor for fuel refining, or in power generation. Moreover, the syngas produced during the process can be recycled back into the system, further enhancing the energy efficiency of the operation.

Conclusion: A Path Towards Sustainability

The innovative solutions offered by Beston Group Co., Ltd., including their pyrolysis machines and thermal desorption plants, play a critical role in solving the world’s plastic waste dilemma. By turning plastic into fuel and refining hazardous waste materials, Beston not only helps companies manage waste more effectively but also contributes to a circular economy where waste is transformed into resources.

For businesses and municipalities seeking sustainable, long-term solutions to waste management, exploring Beston’s pyrolysis machines for sale and thermal desorption technology may be the first step toward a greener future.