Charcoal making furnace is an important tool in the process of making charcoal. The charcoal making furnace is designed to heat the wood to high temperatures, removing all the moisture and volatile compounds, and leaving only the carbon. The resulting charcoal is a highly valued fuel source that has been used for centuries in a variety of applications.

Beston Batch Charcoal Making Furnace Shipped to Spain

Charcoal making furnaces come in many shapes and sizes, but they all work on the same basic principle. The furnace is filled with wood, and then the wood is heated to a high temperature, usually between 400-600 degrees Celsius. The furnace is sealed to prevent the escape of gases and oxygen, which could cause the wood to ignite instead of turning into charcoal.

The furnace is usually heated by burning the gases and volatile compounds that are released during the process of making charcoal. This heat is then used to continue the process, creating a self-sustaining cycle that can continue for many hours. The resulting charcoal is then cooled and removed from the furnace. View this case: charcoal maker machine in the United States.

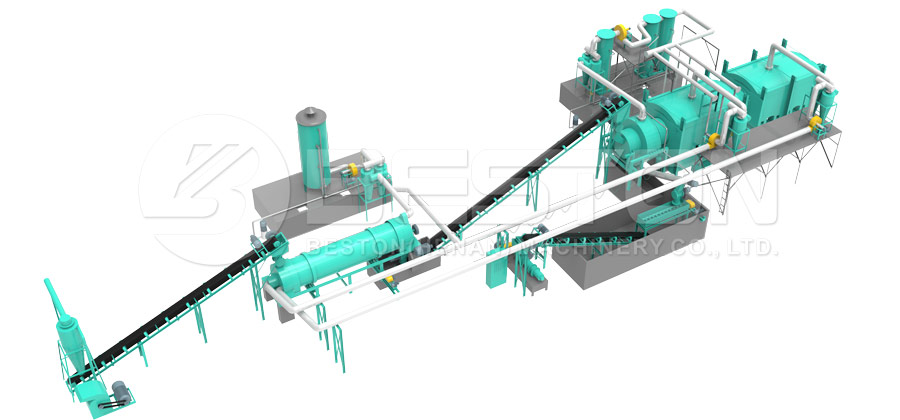

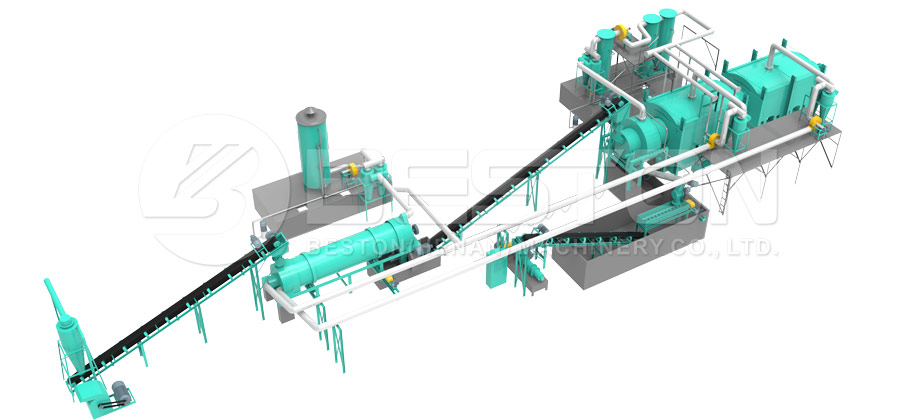

Charcoal Making Furnace

There are many benefits to using a charcoal making furnace. One of the most significant benefits is that charcoal is a renewable resource. Unlike fossil fuels, which are finite and can eventually be depleted, wood can be replanted and harvested sustainably. Charcoal is also a cleaner burning fuel than many other options, producing less carbon dioxide and other harmful emissions.

Charcoal is also a highly versatile fuel source that can be used in a variety of applications. It is commonly used for cooking and heating, as well as for industrial purposes such as smelting metals and producing cement. It is also used in the production of activated charcoal, which is used in many applications including air and water purification. There are some options: https://bestonmachinery.com/bbq-charcoal-making-machine/.

There are many different types of charcoal making furnaces available, ranging from small portable units to large industrial-scale operations. Some are designed for specific types of wood, while others can handle a variety of wood types and sizes. The type of furnace you choose will depend on your specific needs and the volume of charcoal you plan to produce.

In conclusion, a charcoal making furnace is an essential tool for anyone who wants to produce charcoal. It is a sustainable and versatile fuel source that can be used for many applications. There are many different types of furnaces available, so it is important to choose the right one for your specific needs. With the right furnace, you can produce high-quality charcoal that can be used for cooking, heating, industrial processes, and more. If you wanna get some suggestion, contact Beston Group: https://bestonmachinery.com/id/.