In an era increasingly defined by both environmental crises and technological advancements, waste tyre pyrolysis plants are emerging as a beacon of innovation. These facilities are not only mitigating the longstanding issue of tyre disposal but are also transforming a problematic waste product into valuable resources. This article explores the transformative impact of waste tyre pyrolysis technology, detailing its processes, benefits, and the promising future it holds within the global sustainability framework.

Understanding Waste Tyre Pyrolysis

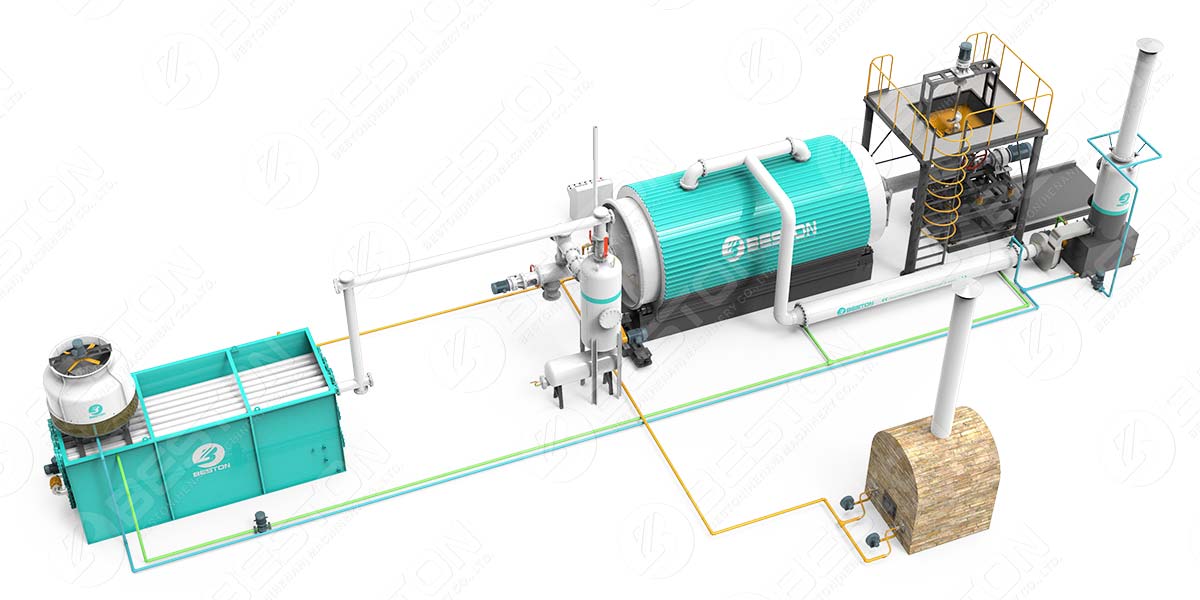

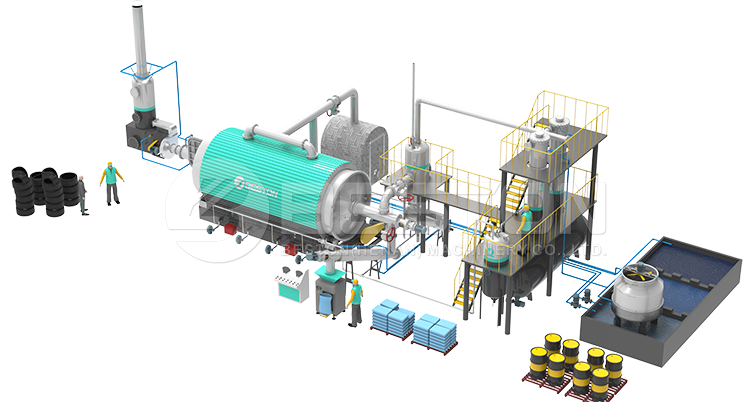

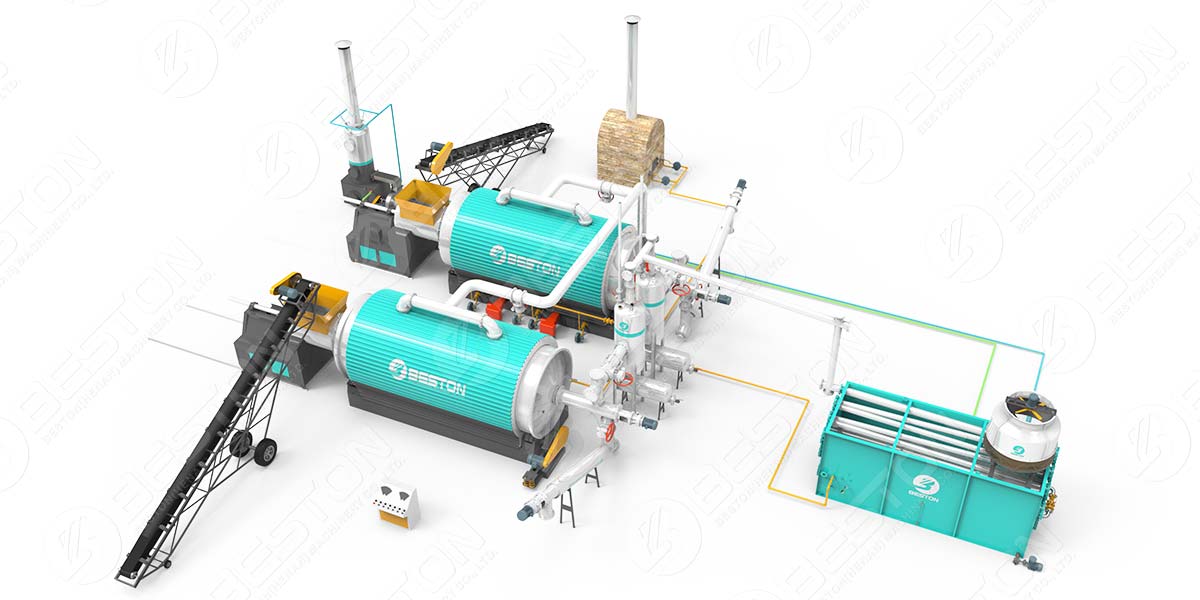

Waste tyre pyrolysis is a method that thermally decomposes used tyres in the absence of oxygen, breaking them down into smaller molecules. The process typically occurs at temperatures between 250°C and 500°C. The main products of waste tyre pyrolysis plant include pyrolysis oil, carbon black, steel wire, and syngas, each with significant utility in various industries.

- Pyrolysis Oil: Often used as a fuel substitute in industrial applications or further refined into gasoline or diesel.

- Carbon Black: Used in the manufacture of tyres, rubber products, inks, and plastics.

- Steel Wire: Recyclable material that can be processed and reused in various manufacturing sectors.

- Syngas: Utilized as a fuel to generate heat and electricity, enhancing the plant’s energy efficiency.

Waste Tire Pyrolysis Plant

Environmental and Economic Benefits

Solving the Tyre Waste Problem: Globally, over 1 billion tyres reach the end of their useful life each year, often ending up in landfills or being incinerated. Pyrolysis offers a sustainable and economically viable solution to this problem, diverting tyres from landfills and reducing the environmental hazards associated with tyre waste.

Reducing Carbon Footprint: By converting waste tyres into usable products, pyrolysis plants help reduce the carbon footprint associated with the production of new materials. For instance, producing synthetic fuels from pyrolysis oil uses significantly less fossil fuel resources than traditional methods.

Creating Value from Waste: Pyrolysis plants turn a waste product into commodities with market value, promoting a circular economy. This not only supports waste reduction but also fuels industrial activities with recycled materials, thereby fostering a more sustainable economic model.

Energy Efficiency: The energy produced during the pyrolysis process can be used to power the plant itself, making it largely self-sufficient and reducing operational costs. More information on continuous tyre pyrolysis plant here.

Market Dynamics and Growth Potential

The global market for waste tyre pyrolysis is poised for substantial growth. Factors driving this growth include the escalating pile-up of waste tyres worldwide and the tightening of global regulations aimed at waste management and landfill use. Governments across various nations are not only encouraging but also investing in tyre recycling technologies, making pyrolysis a focal point of public and private sustainability initiatives.

Moreover, the rise in demand for green, recycled products is amplifying interest in pyrolysis products. Industries such as automotive, construction, and energy are increasingly utilizing recycled materials to improve sustainability and reduce production costs, thereby boosting the market for pyrolysis outputs.

Technological Innovations and Efficiency

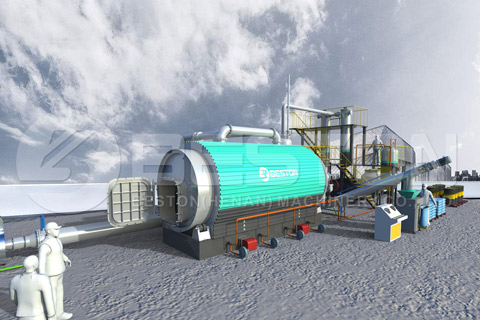

Advancements in pyrolysis technology are continuously improving the efficiency and output quality of these plants. Modern pyrolysis plants are equipped with sophisticated control systems that optimize temperature and processing conditions, maximizing output and minimizing waste. Check the tyre to oil plant here.

Furthermore, research into catalysts and process enhancements continues to open up new applications for pyrolysis byproducts, enhancing their market value and usability. Innovations such as modular pyrolysis units are also making the technology accessible for smaller-scale operations, broadening its adoption.

Key Players and Global Reach

Several pioneering companies are leading the way in the waste tyre pyrolysis sector. Notable among them are:

- Pyrocrat Systems: Known for their efficient and environmentally friendly technology that promises high-quality oil output.

- Beston Machinery: Offers highly customizable and versatile pyrolysis plants that cater to a broad spectrum of industrial needs.

- Klean Industries: Specializes in providing high-end, energy-efficient pyrolysis solutions with a strong focus on reducing emissions and enhancing product quality.

These companies not only provide technology but also engage in active research and development to push the boundaries of what pyrolysis can achieve.

The Road Ahead

The future of waste tyre pyrolysis is incredibly promising. As more nations commit to zero waste goals and circular economy frameworks, the demand for efficient and sustainable waste management solutions like tyre pyrolysis is expected to surge. With continuous technological improvements and increasing governmental support, pyrolysis plants are set to play a crucial role in global environmental sustainability efforts.

In conclusion, waste tyre pyrolysis plants represent a transformative development in waste management technology. By efficiently converting end-of-life tyres into valuable resources, these plants are not only tackling a significant environmental problem but are also contributing to the global pursuit of sustainability. As such, they exemplify the potential for innovative technology to drive environmental progress and economic value in harmony. See the pyrolysis site of pyrolysis plant UK.